Your Quick Guide To Crane Attachments

When it comes to crane operations, having the right attachment can make all the difference. At Mighty Cranes, we have access to a wide range of specialised crane attachments to suit every lifting scenario, whether you’re transporting bulky materials, lifting personnel safely, or relocating heavy machinery. With the right tools for the job, you’ll not only boost efficiency but also improve safety and compliance on-site. In this quick guide, we’ll walk you through some of the most common crane attachments available and how they’re used across various industries.

1. Large Goods Lifting Cage

What it is: A large goods cage is a heavy-duty cage built with reinforced steel to handle oversized or bulky items. Goods cages need meet Australian Safety Standard AS4991, and be tested, tagged and have a compliance plate and serial number attached before they can be used on an Australian worksite.

Used for: It is designed to lift large and awkward products and for Transporting large materials like frames, sheet goods, or machinery components securely across a construction site via crane. It is ideal for the cabinetry, air conditioning and glazing industries, and to lift products safely onto high rise constructions.

2. Standard Goods Cage

What it is: A standard goods cage, sometimes known as a solid sheet metal goods cage, is an enclosed lifting cage with solid walls and secure access points. A goods cage needs to meet AS4991 and comply with Australian worksites laws which requires testing, tagging and have a compliance plate attached.

Used for: It is designed to safely moving smaller tools, loose items, and building materials that could otherwise shift or fall during lifting.

3. Crane Forks

What it is: Crane forks, or crane lift pallet hooks, are adjustable forks similar to those on a forklift, designed to attach to a crane hook. Crane lift pallet hooks must be designed to meet Australian Standard AS4991.

Used for: They are designed for the overhead lifting of palletised loads such as bricks, tiles, or building supplies where precision placement and flexibility are needed.

4. Crane Forks Cage

What it is: A cage attachment that works in conjunction with crane forks to encase the load.

Used for: Enhancing safety during lifts by preventing palletised materials from slipping or toppling, especially at height.

5. Personnel Access Cage

What it is: A personnel access cage, or crane man cage, is a secure platform fitted with rails, gates, and safety features for personnel access. These units need to be individually proof load tested in accordance with AS4991, tagged and have compliance plate and serial number attached.

Used for: Crane man cages are used for lifting workers to elevated work areas for maintenance, inspection, or installation tasks while maintaining compliance with safety standards.

6. Rescue Cage

What it is: A first aid rescue cage is a robust lifting cage specifically designed for emergency and medical response. In Australia, crane rescue first aid cages must be made available and readily accessible on the work site as an effective emergency response. Crane Rescue Cages must be designed to meet Australian Standard AS1418.17. In Queensland, they also need to be designed and registered to comply with the QLD Tower Crane Code of Practice 2017 (PN12040).

Used for: For the emergency retrieval and first aid rescue of injured workers from difficult-to-reach areas on a worksite quickly and safely, with space for a stretcher and support personnel.

7. Stretcher Workbox

What it is: A larger emergency cage that accommodates both a stretcher and responders.

Used for: On-site emergencies where both casualty and medical personnel need to be lifted together, especially on high-rise or remote job sites.

8. Forklift Access Cage

What it is: A forklift access cage, or forklift safety cage attaches to a forklift for safe elevation of personnel. Forklift safety cages further expand the use of forklift trucks by allowing them to be used to transport and lift personnel. This is especially useful in manufacturing and warehousing processes that involve high-access work, goods storage and order picking. They must be designed to comply with stringent quality controls and AS2359.1 for work platforms and AS1891.4 for harness attachment points.

Used for: Carrying out tasks such as lighting maintenance, stocktake, or light repairs where working at height is required without the use of a crane.

9. Gas Bottle Cage

What it is: A purpose-built cage with restraining mechanisms to hold gas cylinders securely.

Used for: Lifting and transporting gas bottles on-site, minimising risk and ensuring compliance with safety protocols.

10. Gas Bottle Trolley

What it is: A Crane gas bottle trolley is a purpose-built trolley designed to carry gas cylinder bottles that need to be pushed or crane-lifted around the worksite. Gas bottle trolley frames need to be tested and certified to meet AS4991, then tagged and supplied with a rating plate.

Used for: They are a safe way to move and lift gas bottles via a crane and are ideal for use on constructions sites where traditional trolleys may be difficult to manoeuvre.

11. Excavator Lifting Platform

What it is: A heavy-duty platform specifically designed to support the weight of an excavator.

Used for: Securely positioning an excavator on the platform so it can be lifted by crane and relocated—ideal for accessing hard-to-reach or elevated work areas where driving the excavator is not feasible.

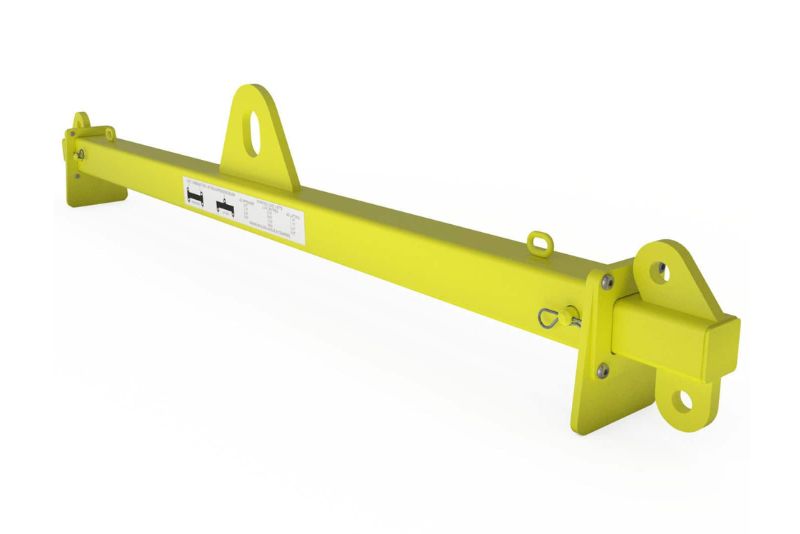

12. Adjustable Lifting Beam

What it is: An adjustable lifting beam, or combination beam, is a multi-point beam with adjustable lifting positions. These units are ideal for crane work where loads and centres often vary greatly.

Used for: Balancing uneven or varying-size loads, offering flexibility for different load configurations during hoisting.

13. Pod Lifting Frame

What it is: A rigid frame built to cradle and lift prefabricated modular pods.

Used for: Lifting entire bathroom pods, site offices, or container-style buildings during installation or repositioning.

14. Bulk Bag Lifting Frame

What it is: A bulk bag lifting frame is a device with attachment points for the crane lifting of large industrial bulk bags (FIBCs). Bulk bag lifting frames need to be proof load tested to meet AS4991.

Used for: Hoisting materials like landscape supplies, sand, gravel, or cement efficiently and safely from ground to level, that are stored in bulk bags.

15. Portable Toilet Lifting Frame

What it is: A specialised frame that securely holds portable toilets during lifting.

Used for: Moving portable amenities to and from elevated construction zones without risk of tipping or damage.

16. Glass Lifting Frame

What it is: A frame with gripping or support elements designed to hold glass panels.

Used for: Lifting and placing glass panes on buildings or shopfronts, essential for reducing breakage and ensuring worker safety.

17. IBC Lifting Frame

What it is: An IBC lifting frame is a secure lifting solution for Intermediate Bulk Containers (liquid tanks). It is a safe and easy way to lift and transport liquid storage containers.

Used for: Hoisting chemical or water-filled IBCs, typically in industrial or manufacturing environments.

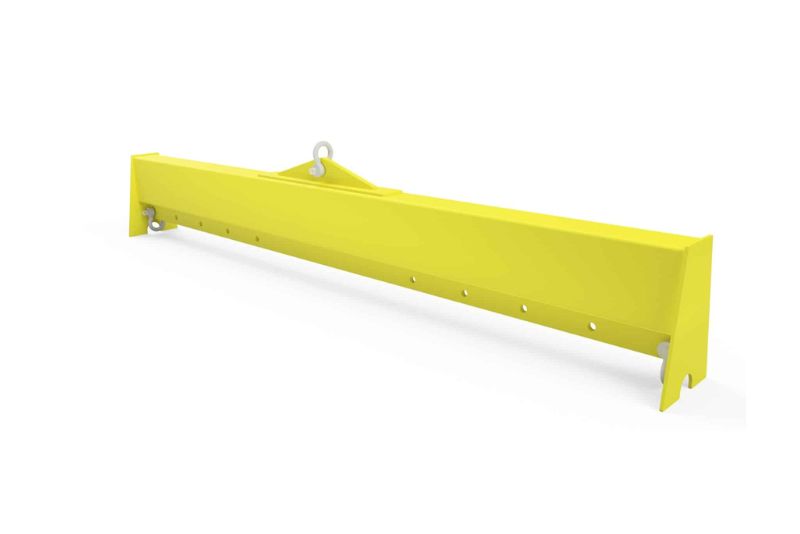

18. Standard Lifting Beam

What it is: A crane lifting beam is a horizontal beam that connects to crane hooks and spreads the load. It is a great solution for your set lifting and rigging work, where the load remains constant and typically under an overhead gantry crane.No 17

Used for: Hoisting long or flexible items like pipes, beams, or bundles while preventing bending or swing during the lift.

19. Block Grab

What it is: A mechanical grab with adjustable arms that lock around concrete blocks.

Used for: Lifting masonry blocks without pallets, ideal for quick and secure loading or stacking on construction sites.

20. Mechanical Precast Grab

What it is: A specialist grab designed for lifting precast concrete panels or elements.

Used for: Handling heavy precast items like walls or stairs with precision, aiding fast and accurate installation in large builds.

21. Crane site bin

What it is: A crane site bin is a fully welded bin supplied with four leg lift system to easily hoist and dump bin contents. It is stackable when empty. Crane site bins need to be certified to meet AS4991 and proof load tested.

Used for: A crane site bin is used to hoist product and then empty it quickly using the rear leg lift points. It is commonly used in industries such as manufacturing, mining, construction, warehousing, and waste disposal.

22. Drum Grab

What it is: A crane drum grab is a unique Australian designed device which provides a safe and reliable way to lift, shift and manoeuvre 205 litre drums. It can be fitted to any lifting device, is self-centering and has the ability to lock on without coming off until required. It has a rated capacity of 1 Tonne.

Used for: A drum grab is used to safely lift and move steel or plastic drums.

Always purchase crane lifting attachments from a quality materials handling equipment manufacturer that meets Australian Standards such as Bremco Metal Products.

Choosing the right crane attachment is essential for maximising safety and productivity on the job site. Whether you’re handling bulk materials, relocating an excavator, or performing elevated maintenance tasks, Mighty Cranes has access to the equipment and expertise to get the job done right. Not sure which attachment suits your project? Get in touch with our team today for expert advice and reliable crane hire solutions in Brisbane tailored to your needs.